CETAL INDUSTRIAL ELECTRIC HEATING ELEMENTS

CETAL INDUSTRIAL ELECTRIC HEATING ELEMENTS

CETAL are specialists in the design and manufacture of industrial electrical heating. Its technological capacity allows clients the possibility of designing and of making the equipment that adapts to the specific necessities that they may require.

Screw threaded immersion heaters

Formed by 2 or 3 cross brackets welded on a stainless steel or brass cork in the models standard, under demand. 230 circuits to V (the connection bridges are included) Cover for optional thermostat.

Maximum working pressure 15 bar length, always warmed up length must be submerged..

| Models of Stainless Steel AISI 321 | Heating elements in stainless steel AISI 321. Brass screw coupling. Load specifies 2 W/cm2. Suitable for air, oil and heavy fuel.. |

| Models of Stainless Steel AISI 316 | Heating elements in stainless steel AISI 316. Brass screw coupling. Load specifies 4 W/cm2. Suitable for thermal oil and water. |

| Models of Copper | Copper heating elements. Brass screw coupling. Load specifies 8 W/cm2. Especially suitable for water. |

| Models in Incoloy 800 | Incoloy 800 heating elements. Brass screw coupling. Load specifies 10 W/cm2. Especially suitable for water. |

| Models in Incoloy 825 | Incoloy 825 heating elements. Brass screw coupling. Load specifies 12 W/cm2. Especially suitable for water. |

Immersion heaters threaded with displaced terminals box

Formed by two or three forks cross soldered on a plug, standard models in brass or stainless steel.

Circuits to 230 V (including the jumpers) suitable for conditions of work in which the temperature of the fluid exceeds 110 ° C.

Terminal box 110 mm. Optional cover for thermostat.

| Models of Stainless Steel AISI 321 | Fitting M45 x 200. Specific load 2 W/cm2 |

| Models of Stainless Steel AISI 321 | Fitting M77 x 200. Specific load 2 W/cm2 |

Heaters for tanks

Fluid Heating. Use in baths/tanks. Consisting of three elements in a spiral and soldered on a plug (standard models) of brass or stainless steel (ODS). 230V circuits (including the jumpers).

Optional cover for thermostat.

| Steel Models AISI 321 | Fitting M45 x 200. Brass screw coupling. Specific load 2 W/cm2 |

| Copper Models | Fitting M77 x 200. Brass screw coupling. Specific load 2 W/cm2 |

Heater coils on ceramic bases

Manufactured with chromium-nickel 80/20 alloy wire. Spiral wound and mounted on a soapstone base.

Mounted in pods which allows replacement without having to empty the container. These pods can be coated with PTFE or other materials so that you can work in media or corrosive acids.

Can be manufactured with diameters of 24, 28, 32, 35, 47 and 58 mm.

Accessories common to all models of threaded immersion heaters mounted on standard fittings of brass or stainless steel.

| Couplings | |

| Nuts & bolts | |

| Flanges for welding | |

| Plugs | |

| Terminal covers | |

| Terminal boxes |

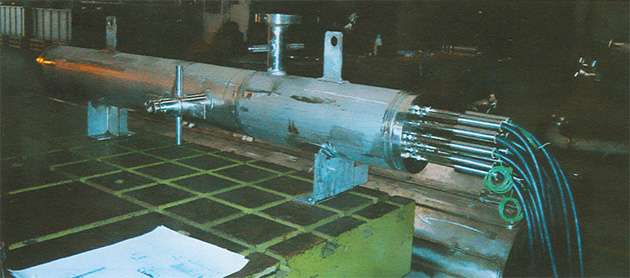

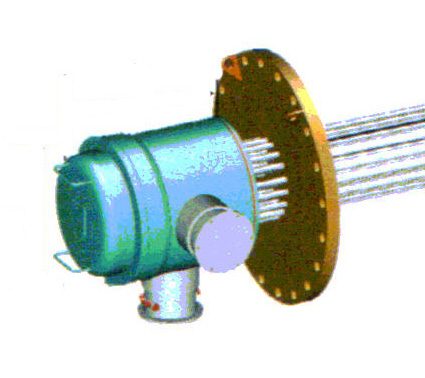

Flanged immersion heaters

These are particularly suitable for heating and maintaining the temperature of large volumes or heating circulating fluids such as water, heavy fuel oil, thermal fluid, air or gas. They can be fitted on tanks, cisterns, boilers and circulation reheaters and are the best electrical heating system for a range of industries such as food processing, chemicals, textiles & plastics etc.

The stainless steel or incoloy armoured elements are generally hairpin-shaped and are welded to the DIN/ASA standardized flanges according to procedures which have CODAP, TÜV and ASME approval.

The watt density, ranging from 0.1 to 15 W/cm², is determined from the working parameters of the process and the exchange coefficients. For a maximum immersion length of 3300 mm, the power delivered by a flange immersion heater can reach several MW.

The electrical cabling in one or more places gives access to several power steps. Connection blocks and rods are used to ensure the electrical connection.

The array may be fitted with a temperature control system whereby the power and specific load are controlled by parameters such as flow rate, pressure, viscosity, temperature etc.

Technical Specifications |

Options |

|

|

These are particularly suitable for heating and maintaining the temperature of large volumes or heating circulating fluids such as water, heavy fuel oil, thermal fluid, air or gas. They can be fitted on tanks, cisterns, boilers and circulation reheaters and are the best electrical heating system for a range of industries such as food processing, chemicals, textiles, plastics etc.

The stainless steel or incolloy armoured elements are generally hairpin-shaped and are welded to the DIN/ASA standardized flanges according to procedures which have CODAP, TÜV and ASME approval.

The watt density, ranging from 0.1 to 15 W/cm², is determined from the working parameters of the process and the exchange coefficients. For a maximum immersion length of 3300 mm, the power delivered by a flange immersion heater can reach several MW.

The electrical cabling in one or more paces gives access to several power steps. Connection blocks and rods are used to ensure the electrical connection.

The array may be fitted with a temperature control system whereby the power and specific load are controlled by parameters such as flow rate, pressure, viscosity, temperature etc.

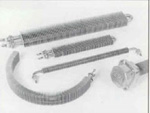

High Performance Elements (THP)

CETAL bolt heaters are specially designed to deliver the maximum power to the heating part. CETAL has developed Boron nitride insulation based bolt heaters, to obtain watt densities that exceed 40 W/cm². These can be used indifferently for tightening / loosening of bolts, for thermal dilation of turbines, for pressure equipments, for drop-forge installations…

CETAL bolt heaters can be equipped with low-voltage connectors, cables, connection boxes, carrying handles. CETAL bolt heaters' technology allows heating to be achieved in a few minutes, thus reducing down-time of pressure equipments and installations considerably.

Technical Specifications

Manufacturing of very high performance elements is the result of the research and development carried out by CETAL during the period 1986 -1987.

This allowed the widening of the application perimeters of heating by the Joule effect which until then was by traditional armoured heating elements (insulation by electrical grade magnesium oxide).

The very high performances of these elements are directly connected to the control of the manufacturing process :

- Positioning of the heating wire as close as possible to the sheath whilst guaranteeing dielectric rigidity.

- Compactness of the insulation (boron nitride) allowing heat transfer and providing electrical insulation when hot.

Boron nitride is used as an electrical insulator to produce stainless steel or incoloy tubular heating elements (diameter 10, 16 or 19 mm). These one- or three-phased elements can be equipped with a core-integrated thermocouple. The watt density, which depends on the operating conditions (convection, conduction and radiation) and on the elements sheath temperature, can exceed 100 W/cm²

Manufacturing of very high performance elements is the result of the research and development carried out by CETAL during the period 1986 -1987. This allowed the widening of the application perimeters of heating by the Joule effect which until then was by traditional armoured heating elements (insulation by electrical grade magnesium oxide).

The very high performances of these elements are directly connected to the control of the manufacturing process :

- Positioning of the heating wire as close as possible to the sheath whilst guaranteeing dielectric rigidity.

- Compactness of the insulation (boron nitride) allowing heat transfer and providing electrical insulation when hot.

Boron nitride is used as an electrical insulator to produce stainless steel or incolloy tubular heating elements (diameter 10, 16 or 19 mm). These one- or three-phased elements can be equipped with a core-integrated thermocouple. The watt density, which depends on the operating conditions (convection, conduction and radiation) and on the elements sheath temperature, can exceed 100 W/cm²

Heaters for acid or corrosive baths

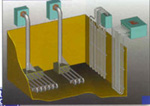

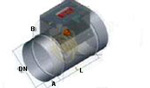

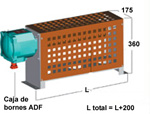

Circulation Heaters

Super STEP heaters. Standard Models

For warming & recirculation of liquids and gases.

Maximum working pressure 15 bar.

Consists of a painted steel body fitted with an immersion heater from series 77, a thermostat that can be scaled from 15 to 95 degrees C, or 80 to 160 ° C.

It has 4 outputs 1 "G.

Total length L + 420 mm.

On request can be made in all stainless steel version.

They can also have lagging.

Series EPMV

Especially suitable for fuel and fluids for heat.

Specific load 2 W/cm2.

Heating element Stainless steel AISI 321, 77V series.

Body diameter 101 mm heater.

Power 230/400 V

Series EPMC

Especially suitable for aqueous solutions and thermal fluids. 4 W/cm2 specific load.

Heating element Stainless steel AISI 316 Ti, Series 77C.

Body diameter 101 mm heater.

Power 230/400 V

Series EPMK

Especially suitable for water. 8 W/cm2 specific load.

Copper heating element, the 77K series.

Body diameter 101 mm heater.

Power 230/400

Super step heater special models

Designed and built for heating or overheating of fluids in forced circulation. Apply to water, superheated water, oil, fuel, steam, air and gases in general.

The heating shields should always be chosen according to the characteristics of the fluid and the temperature, the separators are designed to achieve the highest gear ratio possible.

The heating elements can be fitted with temperature control systems that allow us to tailor the specific charge to the parameters of flow, pressure, temperature, viscosity, surface temperature resistance etc. Can be constructed for use in explosive atmospheres.

Connecting several heaters are available on each joint with a large heating capacity.

Immersion Heaters for open tanks

Suitable for heating liquids in open vats, with low or variable temperatures.

Suitable for heating liquids in open vats, with low or variable temperatures.

Wiring 400 V three-phase star in the standard models. Other wiring on demand.

Stainless steel outlet tube AISI 304 L with a length of 1 meter. Other lengths on demand. Optionally can incorporate a thermostat control.

Different models can be supplied for specific applications.

TB Series for water. Nickel-plated copper tube. 6 W/cm2 specific load

TR Series for water. Nickel-plated copper tube. 6 W/cm2 specific load

DH-Series Oil. AISI 321 stainless steel tube. Specific load 2 W/cm2

PB Series for acid baths. Steel tube coated with lead. Specific load 2 W/cm2

RV Series wine. AISI 321 stainless steel tube. Specific load 2 W/cm2.

Finned Strip Heaters

Made of AISI 321 steel tube, galvanized steel fins on the standard version, or stainless steel. Fittings for assembly are supplied with nuts and gaskets.

Terminals with screws.

Particularly suitable for heating gaseous fluids in natural or forced convection.

Maximum temperature of the tube: 350 º C for standard models.

650 º C for models with stainless steel fins. They are used for building heating.

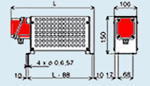

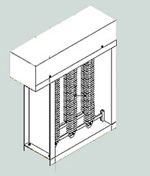

Industrial Radiators

These robust constructed heaters are specially designed for heating industrial premises and work cabins. Thermostats can be equipped with regulation.

The connections are protected by a terminal box.

|

Model RIM Terminal box IP55 aluminum. Finned heating element load 4W/cm ². Outer perforated plate Options: Thermostat 0-40 ° C with external control. See Pdf for more details |

|

|

Model RIT Suitable for heating public buildings Terminal box IP55 painted sheet. Finned heating element charged 2,5 W / cm ². Outer perforated plate Options: Thermostat 0-40 ° C with external control See Pdf for more details |

|

|

Model RE Terminal box IP55 painted sheet. Heating element loaded U-2.5 W / cm ². Outer perforated plate. See Pdf for more details |

|

|

Model RIC Terminal box model ORGM Finned heating element uploaded 4 W / cm ². Equipped with a thermostat 0-40 ° C with external control Outer perforated plate. See Pdf for more details |

|

|

Model RAE T3. Flameproof LCIE Certificate No 94 C 6 R 48X Finned heating Classification Group II T3 Maximum temperature of heating element 200 º C Options: 0-40º wall mount thermostat. See Pdf for more details |

|

|

Model RAE T4. Flameproof LCIE Certificate No 94 C 6 R 48X Finned heating Classification Group II T4 Maximum temperature of heating element 135 º C Options: 0-40º wall mount thermostat See Pdf for more details |

|

|

Model RBAE T3. Flameproof Certificate LCIE n º 00 E 6003X steel tubes and fins Classification T3 Group II Maximum temperature of heating element 200 ° C See Pdf for more details |

|

|

Anti-condensation heaters for electrical cabinets Low temperature heating elements to prevent icing & condensation in cabinets and controllers. Model CHA ** W. Power 10, 20, 35, 45, 70, 90, 150 or 200W Voltage 230V. Others on demand. Cable 500 mm. Standard Thermostat: 20 - 50 ° C. Under request 5 - 35 º C See Pdf for more details |

Industrial & Air-duct Heaters

Constructed with reinforced or finned heating elements, provide solutions to problems of heating air and gaseous fluids.

In addition to the standard series models can be built special models under customer's specifications or technical proposal to provide a solution to a specific heating problem.

|

BTO Series circular conduit Very robust. Air heating application in circular ducts with a minimum speed of 2 m / sec. It incorporates one or more shielded tube heating elements, supported by a T-tube steel pipe, which allows interspersed in standard diameter circular ducts. They include a temperature limiter calibrated to 90 ° C and with automatic reset. 230 V circuits, wiring upon request. Gland for cable entry. |

|

|

BTR Series for rectangular duct Finned elements mounted on a steel bracket for installation in rectangular duct system box IP55 Connection box equipped with a temperature limiter calibrated automatic reset to 90 ° C. 230 V circuits. Wiring three-phase output with stuffing. |

|

|

Serie B. Frame Mounted These models are used to heat the air and nonflammable gases, in forced convection at a maximum temperature of 110 ° C with a minimum fluid velocity of 2 m / sec. Finned heaters are equipped as standard. Galvanized frame with a passage section appropriate to the dimensions of the heaters (see table). 230 V Circuits output with cable gland, mounted on removable plate. Options: cover for thermostat, thermostat, wiring in one or more stages. |

|

|

Special production models Usually used in the air and gas heating to temperatures of 850 º C.para drying, dehydration, heat treatment catalyzing fumes, etc. They can provide equipment for air treatment in explosive atmospheres. The heating elements that constitute these models are specially designed to get the best exchange surface. These elements can be assembled into one or more supports or stainless steel for installation in ducts. They can be supplied wired for one or more stages. Electrically powered, three-phase, can be up to 750 V. Can be equipped with temperature control systems based on the parameters that are deemed necessary. |

Heaters for classified zones

Used in hazardous atmospheres for heating gas or liquids subject to natural convection or forced circulation, CETAL immersion heaters have certificates issued by the LCIE. They meet the requirements of the new European Directive 94/9/EC of 23.03.94 (ATEX) and standards (CENELEC). The different versions – immersion heaters with casings with a component certificate, immersion heaters with a certificate of conformity – the wide choice of possibilities and methods of protection, guarantee a solution suited to the customer's requirements.

Immersion heaters for explosive atmospheres are equipped of stainless steel or incolloy armoured elements, generally hairpin-shaped, welded to the DIN/ASA standardized flanges according to procedures which have CODAP, TÜV and ASME approval.

|

STANDARDS General requirements EN 23-514-wrapper 50014/NFC flameproof "d" 50018/NFC 23-518-Increased safety "e" in 50019/NFC 23-519 TECHNICAL DATA Temperature control of the medium (heating liquids) integrated limiter for thermocouple or resistance on the upper armor. |

|

|

Explosion-proof Immersion Heaters Immersion heaters for explosive atmospheres are equipped of stainless steel or incolloy armoured elements, generally hairpin-shaped, welded to the DIN/ASA standardized flanges according to procedures which have CODAP, TÜV and ASME approval. |

|

|

Explosion-proof air duct Heaters Prepared for use in explosive atmospheres according to EN 50018, these radiators are used for industrial space heating, spray booths, flammable goods stores etc. . External protection sheet. Maximum temperature on the heating element, depending on the temperature rating of Use |

|

|

Explosion-proof Terminal boxes |

|

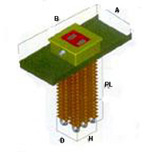

Heaters & specially made equipment

Special Fabrications

Special Fabrications

Can be constructed, upon request, fully finished equipment to meet all industrial requirements:

Heaters, hot tables, thermal, step heaters

They are designed and built according to customer specifications

The heating element is embedded within a body of cast aluminum, brass, bronze, or iron.

They are perfectly suited to extreme operating conditions (shock, vibration etc.). And allow us to ensure uniform heating both flat and cylindrical. The casting is made with a sand mold or metal depending on the number of parts, and mechanical properties required.

They can be equipped with inner tubes, water cooling or thermal fluid circulation for heating compressed air or other gases under pressure. Formando dos semiabrazaderas son una excelente alternativa para el calentamiento de tubos o de reactores. Two half forming clamps are an excellent alternative for heating pipes or reactors.

|

Technical Specifications Power: single-phase or three-phase 230/400V or other demand. · Specific load on the element: 20 W/cm². · Maximum weights: 400 kgs brass 300 kgs. aluminum. · Watertight or flameproof junction box. · Electrical connections for terminal threaded or welded wire on the outputs of the heating elements. · Manufacturing and finishing on-demand · Assembly by screws. · Lagging demand according to temperature. Recomended Working Temperatures Aluminium. 400 C Brass 600 ° C Bronze 650 ° C Casting 750 ° C |

Specialy made Unique models or Series

CETAL can design and manufacture any type of electric heater capable of providing solutions to heating problems in the general industry. While models can be supplied only to a specific case or series of heating elements to incorporate into appliances or production processes. In both cases the manufacture can be made according to customer specifications, or the solution offered by CETAL to the application submitted by the client.

|

GENERAL TECHNICAL SPECIFICATIONS · Power from a few W up to several hundred kW. · Low power and medium voltage up to 1000 v single-phase or three-phase connection. · Use up to 1000 ° C temperatures · Dimensions, based on drawing, specification or sample provided by the client. · Material: copper - stainless steel - incoloy - inconel · Assembly: flange special or standardized accessories, special mounts · Connections: Rod threaded, cables, faston terminals · Connections boxes: standard, watertight antideflagrantes |

|

ELEMENTS FOR DISTRIBUTION BLOCKS They are an excellent alternative to hot plates, particularly for heating distribution blocks in hot runner plastic injection industry. Manufacturing system developed by CETAL ensure high uniformity of temperature along the entire length of the element forming. Power to order. Power: Single phase 230 - 400 V or another. Individual control over template. |

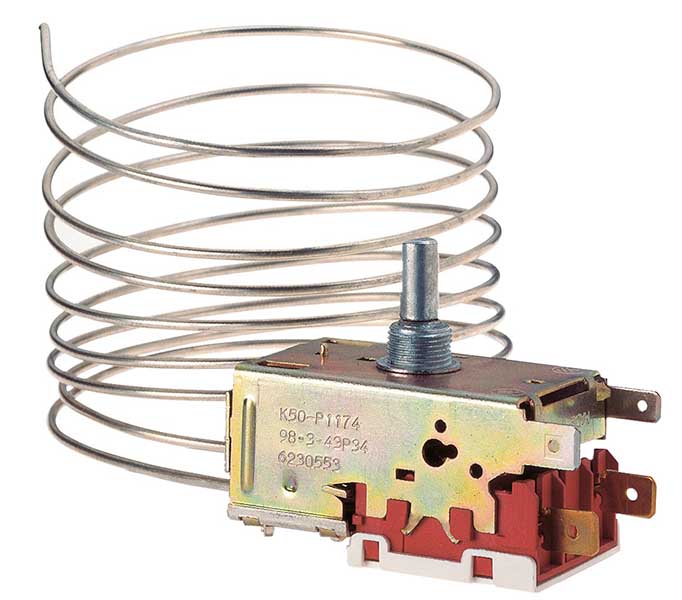

Temperature & control systems

|

CETAL MECHANICAL THERMOSTATS Thermostats specially designed to equip the different models from CETAL heating engineers . They can also be used in industrial applications of temperature control. |

|

|

REGULATION AND CONTROL EQUIPMENT Constructed regulation boxes according to necessities |

|

|

PROCESS REGULATORS They are regulating of two points of intervention, with regulation PID in the first and ON/OFF in the second. The input can be analogical multi-robe or in current or voltage . There are models with outputs for SSR, analogical outputs and communication RS485 |

|

|

TEMPERATURE PROBES Different models of probes, with accessories for applications in diverse fields. In the product section you will find detailed technical information for the different models in pdf datasheets. |

|